Overview

The 5-day Lead Auditor training course aims to provide participants with the knowledge, and develop the skills and expertise necessary to:

-

Audit a Quality Management System (QMS) based on ISO 9001:2015

-

Ensure that the organization is competent in maintaining and continually improving its QMS

-

Perform third party audits by applying widely recognized audit principles, procedures and techniques

-

Proficiently plan and perform internal and external audits in compliance with ISO 19011 and the certification process according to ISO 17021.

-

Manage audit teams and audit programmes, communicate with customers, resolve conflicts, etc.

Based on practical exercises, the participants will master the audit tools and techniques.

ISO 13485: 2016

Lead Auditor

First time you visit our website?

Empower Your Team with Industry-Leading Training Programs

Tailored corporate training for leadership, technical skills and professional development

-

We serve corporate clients investing in peoples' knowledge, skills, and competencies, to improve business performance, enhance process, product and service quality, and achieve sustained growth and profitability.

-

We understand the meaning of the business terms "Voice of the Customer" and what constitutes "value" from the customer's point of view.

-

We also understand the difference between "value" and "waste" from the business and individual learner point of view.

-

-

We care about the people, the knowledge enhancement of which is entrusted to us by their organisation or themselves.

-

We focus on learning (not just on training, and issuing certificates) and providing post-training advice and support through workshops and consulting services.

Stratos Lazaridis

CEO The Marvel Academy

Corporate Training Solutions

Mob: +44 (0)749 114 7156

Background

Lean Thinking was born out of studying the rise of the Toyota Motor Company from a bankrupt Japanese auto maker in the early 1950s to today's dominant global player.

At every stage of its expansion, Toyota remained a puzzle by:

-

Capturing new markets with products deemed relatively unattractive

-

Systematically reducing their operating costs, without following the usual established management practices.

When studying the company closely, it appeared that it had:

-

A unique group of elders, each known as “Sensei”

-

Coordinators, i.e. Japanese (trainers from) dedicated to help managers think differently.

LEAN

-

Thinking

-

Manufacturing

-

Services

-

Office

-

Kaizen

-

Kanban

-

Startup

-

Enterprise

-

Tools

Contrarily to every other large company, Toyota's training in its formative years was focused on developing people's reasoning abilities rather than pushing them to execute specialist-derived systems.

What is “Lean Thinking”?

The term was coined by James P. Womack and Daniel T. Jones, authors of the best-selling book “The Machine that Changed the

World”.

-

The intend was to capture the essence of their in-depth study of Toyota Production System” (TPS).

“Lean” is a word used to reflect the Japanese business approach in performing all aspects of business operations:

-

Using “fewer” people

-

Spending less time

-

Putting less effort

-

Spending less money/ capital

-

Consuming smaller quantities of parts and materials

-

Creating less waste

-

Having fewer accidents.

Lean can be defined as:

-

Set of techniques to identify and eliminate waste (muda) from day-to-day operations.

-

System of organization principles to maximize value and eliminate waste.

Examples of Lean waste:

-

Paying people to stand around waiting for something that is late to arrive

-

Customers waiting in a queue

-

Incurring the cost of inventory, i.e. storing something that has not already been sold

-

Making products no one wants to buy

-

Adding features to a product that the customer has not asked for

-

Producing more than the customer has ordered

-

Being blocked in your programming.

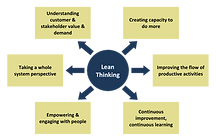

Lean Thinking is a specific way of observing a business task/ activity and identifying the waste inadvertently

generated by the way the process is organized and performed.

It uses the concepts of:

-

Value

-

Value stream

-

Flow

-

Pull

-

Perfection (true North).

What is the aim of Lean Thinking?

The aim is to create the Lean Enterprise, that:

-

Sustains growth by aligning customer satisfaction with employee satisfaction

-

Offers innovative products or services profitably while minimizing unnecessary overhead-costs to customers, suppliers, and the environment.

The insight of Lean Thinking is that if you train every person to:

-

Identify wasted time and effort in their own daily job, and

-

Work together to improve processes by eliminating such waste, then …

... the resulting Lean Enterprise will deliver more value at lower cost, while developing every employee's confidence, competence, and the ability to work with others.

Lean Thinking vs. Lean Manufacturing

The idea of Lean Thinking gained popularity in the business world, and has evolved in two directions:

-

Lean Thinking

-

Lean Manufacturing.

Lean Thinking

Lean Thinking is a business management philosophy aiming to provide a new way of thinking about how to organize

human activities to deliver more benefits to society and value to individuals while eliminating the 8 forms of Lean waste (muda).

Lean Thinking converts are seeking to understand how to achieve dynamic gains rather than static efficiencies.

For this group of thinkers, Lean Thinking:

-

Continuously evolves, as they seek to better understand the possibilities of the "Toyota Way"

-

Is about practising Kaizen (continuous improvement), the purpose of which is to achieve small incremental improvements, made every day, by everyone, everywhere using Lean tools and techniques

-

Is a movement of Lean practitioners and writers who experiment and learn across different industries and conditions, to “Lean-think” any new operational activity.

Lean Manufacturing

Modern management philosophy inspired by the Japanese concept of Kaizen, the strategy of

continuous improvement, that aims to eliminate waste in the production system.

-

It is like getting rid of unnecessary “fat” and waste in the workplace that has no added value to a product.

The goal of Lean Manufacturing is to improve and speed up production by eliminating quantifiable

waste as far as manufacturing/ production is concerned.

Lean Manufacturing adepts have:

-

Interpreted “Lean” as a form of operational excellence

-

Turned to company programmes aimed at reducing operating costs associated with core business processes.

The Lean Production approach is the reason why Toyota has been so successful in their chosen

industry for decades.

-

It is also the reason why manufacturing industries world-wide are adopting the same Japanese production

discipline, to varying scale and style, to achieve the same level of success as Toyota.

Critics of Lean Manufacturing point out that:

1. Lean manufacturing activities:

-

Are used to improve business processes without challenging the underlying thinking

-

Although they achieve impressive results with "fruits on the ground" and "low-hanging fruits", an analogy used for identifying and eliminating "easy waste", have little hope of transforming the culture of the enterprise.

2. The “corporate Lean” approach is fundamentally opposed to the ideals of Lean Thinking

-

However, it has been taken up by a great number of “big” businesses, seeking to cut their operating costs without challenging their fundamental management assumptions.

What is “Lean Enterprise”?

An organisation where everyday, everyone, everywhere practices Lean Kaizen.

-

The term "Lean Enterprise" refers to a production principle stating that any component that fails to directly

add value/ benefit a final product is superfluous.

The Lean enterprise:

-

Is a practice focused on value creation for the end customer/ user with waste and processes.

-

Focuses on value creation and delivery in the form of products and services while waste and non-essential

processes.

The term has historically been associated with Lean Manufacturing and Six Sigma (or Lean Six Sigma) due to:

-

The Lean principles being popularized by Toyota in the auto mobile manufacturing industry

-

Lean Thinking and Lean Manufacturing being subsequently popularised in the electronics and internet

software industries

-

Six Sigma being introduced by Motorola and popularised by General Electric (GE) under the leadership of

CEO Jack Welsh.

The Lean Enterprise aims to:

-

Eliminate waste.

-

Build quality in.

-

Create knowledge.

-

Defer commitment.

-

Deliver fast.

-

Respect people.

-

Optimize the whole.

Lean Enterprise = Green Enterprise

The importance of Lean Thinking goes beyond improving business profitability.

In their seminal book “Natural Capitalism”, authors Paul Hawken, Amory Lovins and L. Hunter Lovins explicitly reference "Lean Thinking" to achieve profitable and sustained business growth, whilst minimising the impact of operational activities on the environment.

-

Lean Thinking seeks to eliminate waste in the form of muri (overburdening), mura (unevenness) and muda (unnecessary resource use) is proven practical way to solve complex business problems through continuous improvement and action-taking.

Toyota industrial sites are:

-

Well-known for their environmental sustainability efforts

-

Ahead of the "zero landfill" goal, where waste is recycled on-site, without need to send waste to the landfill.

Practising Lean Thinking is a radically new way to look at traditional production and delivery of goods and

services to learn how to sustain the same benefits much lower operating cost, both, financially and

environmentally.

We deliver a range of Lean training courses, covering the following topics:

-

Lean Foundation & Practitioner

-

Kaizen Foundation & Practitioner

-

Kanban Foundation & Practitioner

-

Lean Start-up

-

Lean Sponsor

-

5S

-

Process Mapping

-

Root Cause Analysis

-

Value Stream Mapping

-

Lean Kanban

General Information

For general course information please click on the link here.

N.B. Please read our Terms & Conditions (T&Cs) and ask for clarifications, if any, before booking your training event.

Book now to reserve an on-site or online instructor-led training event of your choice.

For more details about our:

-

List of training courses please click here.

-

Consulting services please click here

-

Workshops please click here.

For queries, including non-obligation quotes, please contact us.